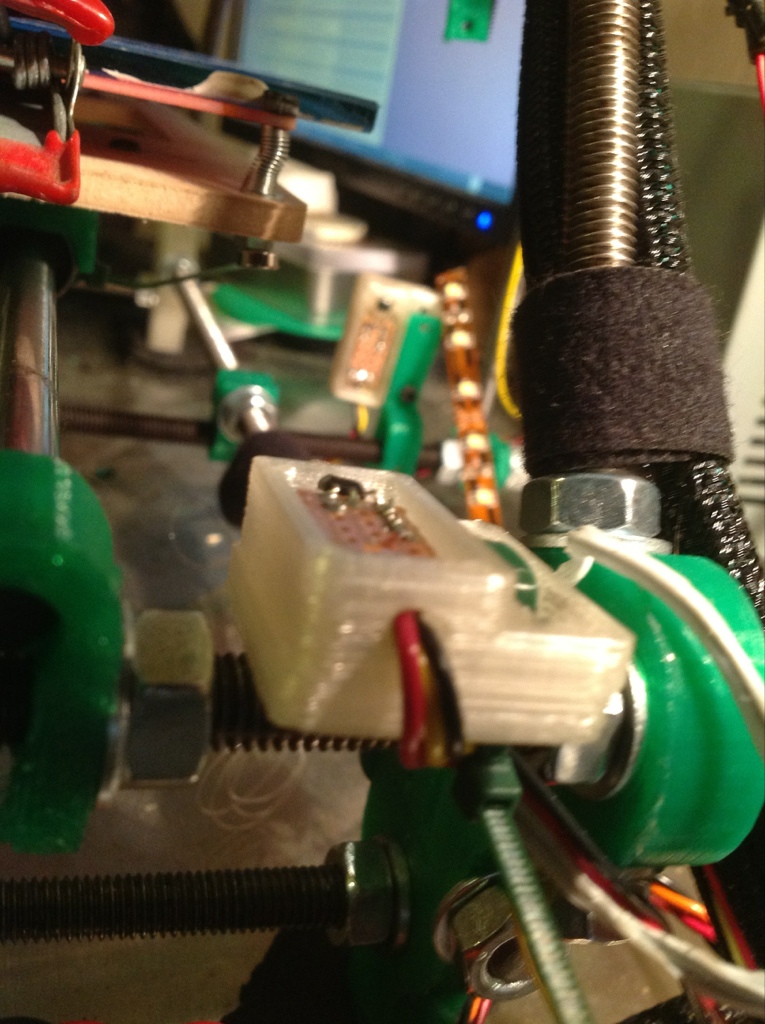

Must print more dome bracket’s. Well I love the newest rendition of the dome brackets with the ball and socket joint thanks to both effalo and yazzo for there work and everyone else who it wouldn’t be possible without. I’ve been making enough to do 1 dome and hopefully get 2 done sometime but sadly I’m waiting on some replacement pully’s for the Mendel. Thanks Kliment And mattymatt. I finally got a really nice pulley printed and wouldn’t ya know it’s the wrong one, well not completely wrong, it just won’t work with a stock sells x carriage. It was the pulleymod off a prusa repo and it’s slightly larger so it grips great just not for the tight radius on the stock sells x carriage. Luckily when I was on irc Kliment offered me some and the timing couldn’t be better since he was shortly receiving another shipment of as card adapters. Oh how I’d love for the Mendel to not need a computer, one day, one day. So until replacement parts arrive i decided to fire up the makerbot and put it to work. Sadly it’s like driving a bug after you’ve had a Porsche for a few months, it keeps working but it ain’t pretty, well perhaps debatable but nonetheless like the beauty of 16x microstepping and a stepped extruder. Oooo la la.

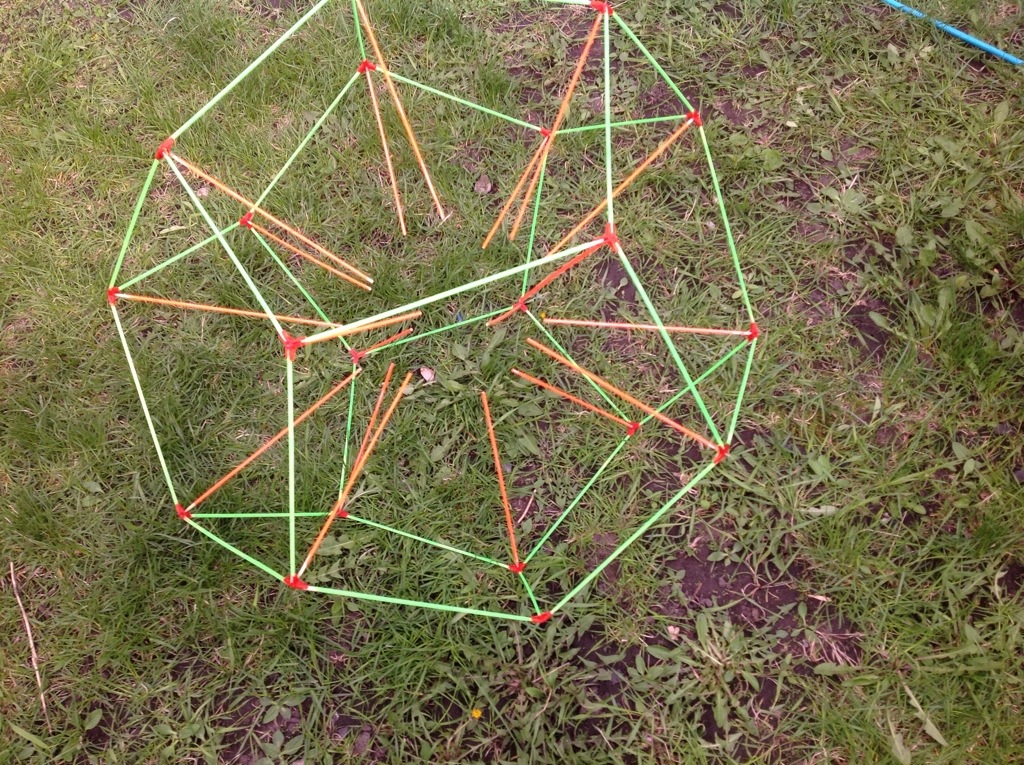

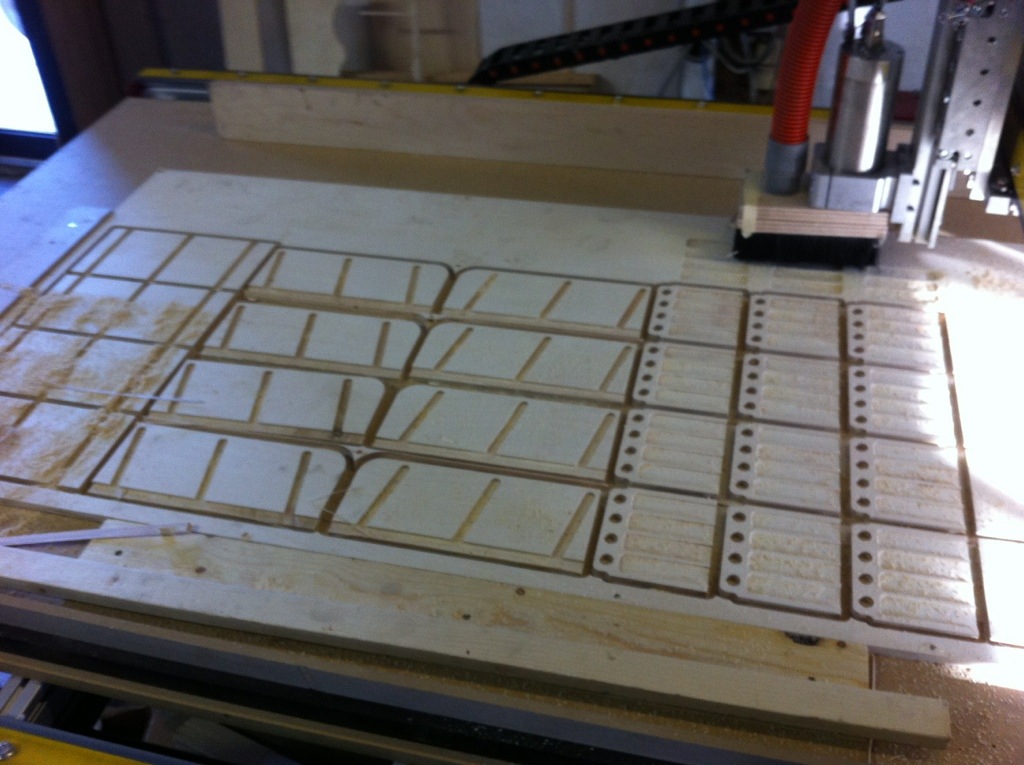

Here’s the progression of the Dome Brackets.

https://www.thingiverse.com/thing:1719

https://www.thingiverse.com/thing:3215

https://www.thingiverse.com/thing:7017

https://www.thingiverse.com/thing:8985