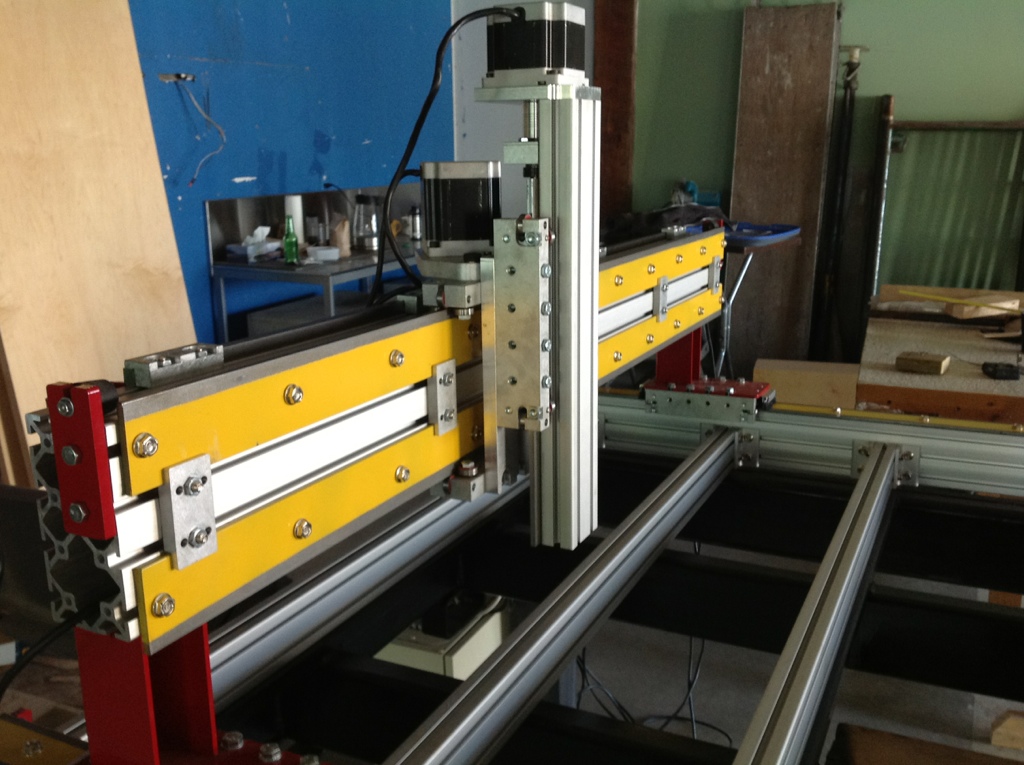

CNC build

I decided on ordering up a kit cnc to use as a proto machine for the new shop. It’s going to be awhile before we hear back from insurance and have a spot worthy of an expensive piece of machinery I figured a kit CNC that you knew exactly how it goes together and open would be a proper starting point. So after digging around on the interwebs for awhile I stumbled across CNC Router Parts. There kit had good reviews and claimed to be “open”. The kit with beefier NEMA34 motors run by a PMDX-126 controller and gecko 201x drivers and prewired electronics was ordered and received. I decided to use Calgary Customs Brokers which seemed to work out fine. The kit included NAFTA certificates, which was a first for anything I’ve ordered, but helped save on boarder charges. One thing that amazed me is that UPS freight is still in business. The pallet was pretty chewed up and most box’s had holes in them, but luckily the packing from cncrouterparts was good enough to save any injury.

The one caveat with there kit is it includes no written instructions. It would be helpful for most people to at least have a few page printout of the various components from a few viewpoints. There pictures online are all an isometric view which obscures some details. I’m also trying to get away from tied up formats and the “free” Solidworks viewer removes the measure tool, at least as far as I got. But other than those small details the kit went together in no time.

Thanks to lots of great tutorials on. Cnc zone forums by a one “tool designer” the finer points of assembling a machine were brought to lite. Often when I’m putting together pieces I get in a zen state where thinking about anything other than tightening this nut and fasting that bolt has little relevance in my current existence. It’s very refreshing to have another approach presented.

The more challenging task I faced next was to get LinuxCNC, formerly called EMC, to function as the brain for this bot. After fumbling around for awhile with no solid progress I decided I’d try mach3. Cncrouterparts supplies a config for mach3 but even that didn’t work, I was doing something wrong what I wasn’t sure. I decided if both of them didn’t work I’d focus my attention on the opensource one and pull out the necessary info from mach3 config. Although it would have been doable I proceeded to download the manual for both the PDMX-126 controller and gecko 201x controllers. There was also a daughter board that just cleaned up the wiring. After finding the right pins in the config I input them to linuxcnc and presto magico we have movement.

I also found a blender Goode plugin which works surprisingly well, another problem to deal with is making a new post for enroute if I still want to use the software.

There’s since been a lot of tweaking and adjusting bearings and rails, until we get the spindle it’s hard to do much more other than pen tests. There still is a few more things to add, home and endstops. There will also be water lines to run and spindle control wires. I have to figure out where to mount the motor box and computer, I should also pickup a monitor arm or make one.

Then I should get the joint’s setup properly with linuxcnc so as to have squareness verification when homed, at least that’s the theory.